Mobile Portable Generator Power Station Sharing Banks Enclosure Injection Molding

Package Size 30.00cm * 30.00cm * 30.00cm Package Gross Weight 7.000kg Sign in Sign in The construction of the injection

Basic Info.

| Model NO. | XY0011 |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Furniture, Commodity, Electronic, Home Use |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | TS16949, CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | After Mold Confirmation, Mold Repair Time Less Tha |

| Instructions | Number of Cycles :> = 800; Service Temperature :-1 |

| Product Size | Product Outer Box Size: 31X21.2X29.2cm Accessories |

| Product Name | 600/1200wh Power Bank |

| Battery Capacity | AC Output :100V-3A 50Hz 600W Sustained Peak 1000W |

| Certificate | PSE, IEC62133 Battery Report, Meti Record, Un38.3 |

| Nearest Port | Shenzhen |

| Battery Type | Lithium-Ion Battery |

| Protection System | Over Charge Protection Over Discharge Protection O |

| Hot Runner | Manufacturer/Factory, Trading Company |

| Injection System | Hot Runner |

| Transport Package | Marine Shipping Container |

| Specification | 275*170*215MM |

| Trademark | OMMO |

| Origin | China |

| Production Capacity | 600 Piece/Year |

Packaging & Delivery

Package Size 30.00cm * 30.00cm * 30.00cm Package Gross Weight 7.000kgProduct Description

Sign in

Sign in| product name | 1500W/1050Wh power bank |

| Battery Capacity: | AC output :100V-3A 50HZ 1500W sustained peak 1000W AC rated output power 1500W |

| DC input | 20V-5A (supports 12V-24V) |

| battery type | Lithium-ion battery |

| Protection system | over charge protection over discharge protection over current protection over temperature protection short circuit protection over voltage protection |

| product size | Product outer box size: 31X21.2X29.2CM accessories box size; 30.5X19.1X4.4CM Outer box packing size: 32.5X22.5X31CM |

| Instructions | Number of cycles :> = 800; Service temperature :-10-40 degrees; Charging temperature :0-40 |

| Certificate: | PSE, IEC62133 Battery report, METI record, UN38.3 MSDS ROHS CE EMC LVD FCC Marine and Air Inspection Report, drop test report. |

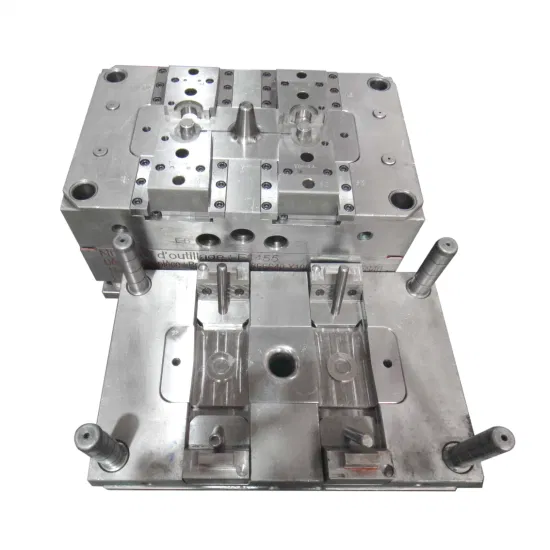

The construction of the injection machine

A general injection machine consists primarily of an injection unit, a mold closure unit, a hydraulic transmission system, and an electrical control system. The main function of the injection device is to uniformly plasticize the plastic by injecting a certain amount of molten material into the cavity of the die with sufficient pressure and velocity..The injection device is mainly composed of (screw. The plasticized parts of the cylinder and nozzle, as well as the hopper, transmission, measuring apparatus, injection and moving cylinder, etc.

1 Mold closing device:

Its function is to enable the opening and closing of the die, to ensure the reliable closing of the die during injection, and to remove the product..The mold closure device consists mainly of a front and back fixed template, a moving template, a tie rod connecting the front and back templates, a mold closure oil cylinder, a link mechanism, an adjustment device, and a product ejection device.

2 Hydraulic and Electrical Control System:

Its function is to ensure that the injection machine is accurate and effective according to the predetermined requirements of the process (pressure, speed, temperature, time) and action sequence. The hydraulic system of the injection machine consists mainly of various hydraulic components and circuits and other auxiliary equipment, while the electrical control system consists mainly of various electrical appliances and instruments..The hydraulic and electrical systems are organized organically together..Provide power and control to the injection machine

Send to us